Technology and machinery

A wide range of production technologies, from the most modern to the most traditional, highly flexible and productive, enables the realization of large batches and sub-assemblies. We manufacture our own products, but our machines are also there for your use.

The machine park consists of 200+ machines. The following is a selection from it.

Flat formingcold

Pulling processes the input material by pulling it through a hole in the mould. This creates a cavity in the product or a seamless tube.

Folding bends the material around the edges or curves of the tools. It can be a single-cycle process producing a relatively simple shape, just as it can produce a very complicated product in multiple cycles.

Shearing separates the excess material to produce the desired shape from the material. Shearing and folding are usually linked in successive cycles to achieve the required productivity.

Steel and aluminium are the most commonly processed materials. Other materials with sufficient plasticity can also be worked with.

The advantage is the preservation of the mechanical properties of the material. The low energy consumption and environmental impact are interesting.

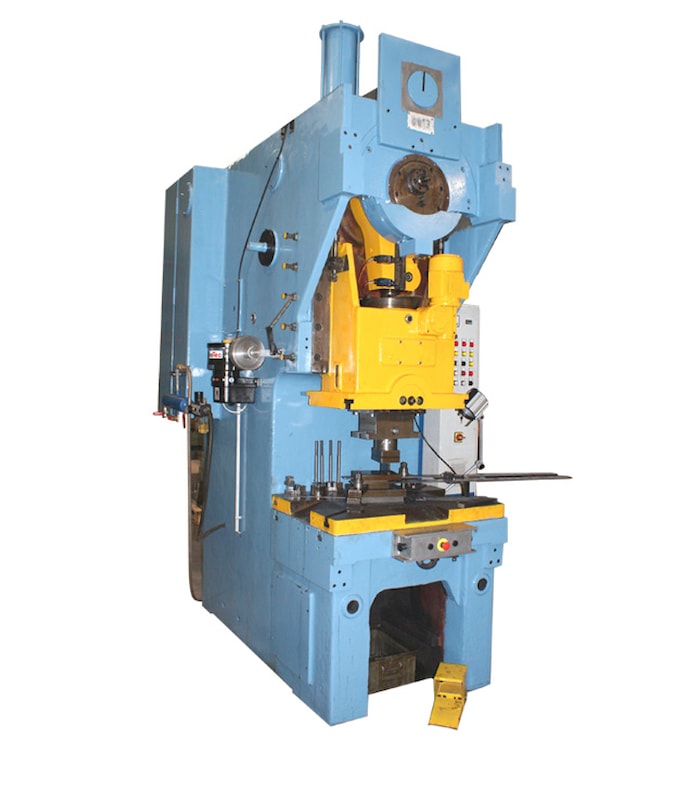

Volume forming

cold

By high pressure of the press, the material is gradually shaped into the final form, which is usually a semi-finished product for further processing or refinement.

Various steels are typical materials.

The advantage is to achieve a higher strength and hardness of the material that the input material did not have. The cost-effectiveness is due to working without heating the material and the fact that no waste is generated, which also reduces the environmental burden.

Machiningchip

Milling removes excess material from the workpiece using a rotating milling tool, which can be of various shapes and sizes. It creates surfaces, grooves, holes and even intricate product shapes or holes in the product.

Turning removes excess material from the workpiece, which rotates rapidly around a longitudinal axis while the tools move along the product. This creates cylindrical and conical shapes with almost unlimited profile shapes. Simple shafts can be created, but also very complicated shapes.

Steel, aluminium but also a range of other, even non-metallic, materials.

The advantage is the very high shape flexibility and precision of the product. There is no need to create expensive moulds. Changes are achieved by changing the program of the control unit. The technology is also effective for small, low volume production runs.

Machiningelectrospark

Electric discharge between two electrodes is an unconventional method. EDM - Electrical Discharge Machining is mainly used for the production of moulds, prototypes.

Hard and resistant materials difficult to machine with other tools.

The advantage is especially the very high precision of machining and reworking even very small details.

2D CuttingCO2 laser

A laser beam focused by an optical system into a small diameter with high precision using thermal energy dissolves or vaporizes the material to be processed. This results in precise and clean cuts and surfaces.

Steel, aluminium, stainless steel and hardox in sizes up to 3x2 m.

The advantage of high precision as well as very accurate and detailed cuts. Noteworthy is the relative speed of cutting, compared to traditional methods, as well as the minimized material trimming thanks to the optimization and control software of the machine.

Weldingmanual and robotic

MIG/MAG welding in a welding bath protected by shielding gas, where the welding wire is fed at a set speed through the welding gun.

TIG welding is a manual operation where the welding wire is fed into the gas protected welding bath by hand.

Automatic welding presses allow unattended welding of elements in large series. The high performance is mainly due to the automatic insertion and positioning of individual components.

Manual welding presses are powerful welding machines with upper and lower clamping plates used for welding series where it is not worthwhile to automate the process.

The main advantage is the wide range of technologies we have in this field, including a modern welding shop equipped with the necessary handling equipment and quality personnel.

3D printingadditive

An additive process where material is gradually applied layer by layer to eventually create a 3 dimensional object. The process differs from traditional methods where the product is created by removing excess material. It is preferably used in rapid prototyping, but also for specific products.

The wide range of materials allows highly variable physical properties of the final production.

The design freedom allows the printing of complex geometric shapes and structures that would be difficult or impossible to produce by other methods.

Rapid prototyping of products greatly accelerates not only the development process, but also gives the opportunity to verify the functionality of the products being developed before the expensive tooling required for mass production by other technologies.

Wasteless technology reduces costs and environmental impact.

Wet coating

The application of the liquid paint is done with a spray gun using compressed air.

The quality of the coating and the resulting appearance is fundamentally influenced by the spray speed, air pressure and nozzle width.

The main advantage is the almost unlimited size of the painted objects.

Powder coating

The application of powder paint, which is electrostatically charged by a special device, is carried out with a special gun. The electrostatic charge ensures uniform coverage of the entire surface.

Curing takes place in a firing oven where the powder paint is melted and the surface subsequently cured.

The advantage is the uniform coverage of even hard-to-reach areas, resistance to abrasion, chemicals and weathering. Powder coating is very economical due to minimal material loss. The method is also environmentally friendly, as it does not require the use of solvents and thus minimises air emissions.

Interested in using one of our technologies or getting information?

Contact us!

The above mentioned technologies represent only a small list of our machinery. If you need metal processing, please do not hesitate to contact us.